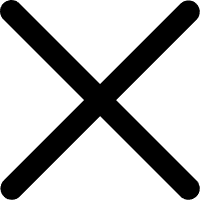

Water generator

Product introduction

Our company represents well-known Marine and industrial equipment manufacturers, whose water machine products are widely used in ships and offshore platforms. The water machine converts seawater into fresh water through advanced distillation, reverse osmosis and other technologies to meet the drinking, domestic and industrial water needs of ships and Marine facilities. They are known for their efficiency, durability and energy saving, ensuring reliable operation in the harsh environments at sea.

Application scenario:

Commercial vessels, offshore platforms, Marine rescue and research vessels.

Main product types and features:

1. Distilling machine

Using waste heat or electricity generated by ship engines, seawater is evaporated and condensed into fresh water.

Main features:

High efficiency: Waste heat from the ship's main engine is used for distillation, minimizing energy consumption.

Compact structure: The design is compact, takes up less space on the ship, and is suitable for various types of ships.

Easy to operate: With an automated control system, the operator only needs a small amount of intervention to ensure the normal operation of the equipment.

Excellent water quality: The effluent quality is high and meets the fresh water standards for ships stipulated by the International Maritime Organization (IMO).

Corrosion-resistant materials: Key components are made of high-quality stainless steel or corrosion-resistant materials, adapted to the high salinity and humidity in the Marine environment.

2. Reverse osmosis water machine

Seawater is converted into fresh water by passing it through a semi-permeable membrane at high pressure, filtering out salts and impurities.

Main features:

High water yield: The use of advanced reverse osmosis membrane technology can efficiently generate large amounts of fresh water, suitable for large ships and offshore platforms.

Energy-saving design: Use energy-saving technology to optimize high pressure pumps and energy recovery systems to reduce operating energy consumption.

Modular design: Modular structure, easy installation and maintenance, suitable for the compact space of the ship or platform.

Water quality control: A sophisticated filtration system ensures excellent effluent quality, suitable for drinking and domestic water needs.

Automatic control: Equipped with automatic control panel and fault detection system to simplify operation.

3. Low temperature evaporative water machine

Low temperature evaporation technology is used to reduce energy consumption by reducing the evaporation temperature.

Main features:

Low energy consumption: Using low temperature evaporation technology to reduce heat consumption, especially suitable for waste heat recovery systems.

Stable operation: Stable fresh water production and operation, adapted to various Marine environments.

Low maintenance requirements: Designed to be durable, reducing frequent maintenance and operation requirements.

Environmental design: Reduce carbon emissions and meet international environmental standards.

4. Multi-effect evaporative water machine

By dividing the evaporation process into multiple stages, the steam from each stage is used to heat the seawater in the next stage, thereby increasing efficiency and reducing energy consumption.

Main features:

Efficient energy use: Reduced energy consumption through multi-effect evaporation, suitable for ships and platforms that require large amounts of fresh water for long periods of time.

Large output: the heat energy of each stage is used many times, and the water output is larger.

Long life design: The use of high-quality materials to reduce corrosion and wear, extend equipment life.

5. Marine compact water machine

Suitable for smaller vessels or offshore platforms requiring a limited supply of fresh water. Usually light structure, easy to install, simple operation, suitable for limited space occasions.

Main features:

Small size, light weight: Compact design, suitable for installation in tight cabin or platform space.

Easy operation: With a high degree of automation, users can easily operate and monitor the operation of the equipment.

Flexible installation: It can be flexibly installed according to the layout requirements of the ship or platform, and has strong adaptability.

Economy: Reduce operating and maintenance costs while maintaining efficient water production.